NOx Reduction by SCR Catalyst on Ships

NOx reduction for a cleaner shipping

H+H Engineering & Services meets every challenge and delivers flexible NOx reduction solutions for your application.

For perfect final results, we focus on excellent planning. For us, customer satisfaction begins with consultation and

with detailed planning that takes your requirements into account from the very beginning. This is how we create innovations

and solutions that are perfectly customized to your needs and guarantee reliability for our customers.

Perfect planning from the very beginning

This is ensured by competent employees who support you throughout the entire project phase and

combine extensive know-how with the best advice.

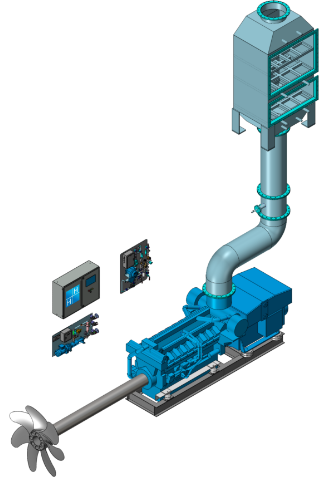

H+H SCR Marine Systems will be different approach for new building and retrofit systems.

Thanks to almost 30 years of experience in this highly specialized field of business,

gained from more than 300 ships in service we can provide the perfectly engineered solution for a perfectly

engineered ship – this all with competitive price level.

The high performance SCR Systems by H+H are for new build and retrofit vessels for operation on

GO, MDO and HFO being designed to meet Tier III NOx, U.S. EPA Tier 4 Final and Stage V limits.

Why H+H makes the difference and should be your first choice for marine SCR solutions

» Compatible for all engines from 200 kW to 60 MW

» All components made in Germany – quality out of one hand!

» Fully extruded catalyst designed by H+H with best mechanical stability

» Urea mixer and 2-phase nozzle for fine atomization and even distribution of urea

» In-house competence of PLC Programming based on Siemens

» High spare parts availability

» Worldwide service locations and representations

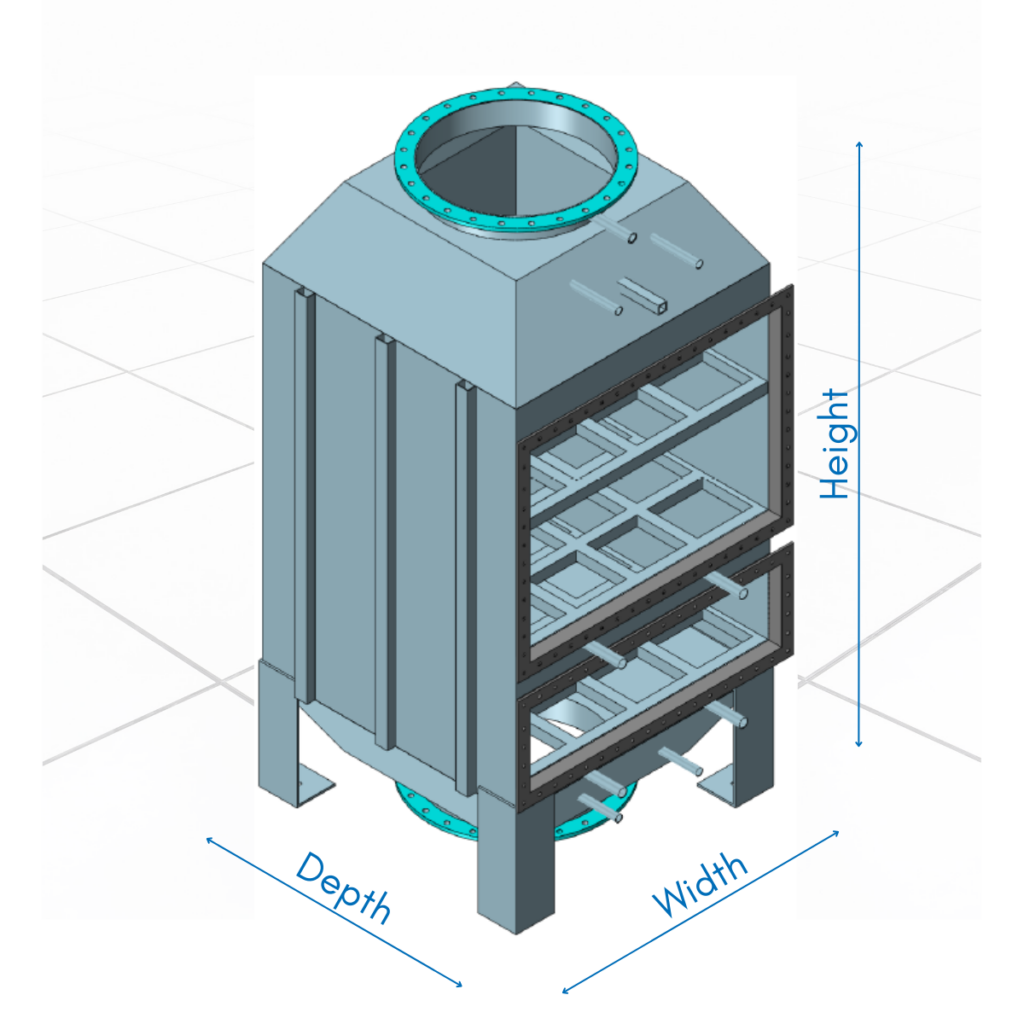

Flexibility in design

Design made in house

Our engineers are trained to design the catalyst housing tailor-made to adapt the SCR system to your specific space requirements.

Very good mechanical stability

Catalyst design by H+H

Specific know-how and well experienced.

Easy transport, handling and installation.

Flexible Design for every installation situation on your vessel!

Emission laws

Ship engines produce harmful nitrogen oxides during combustion. These emissions from maritime shipping have serious consequences for human health. For this reason, strict national and international legal requirements must be observed. The NOx limits are being reduced step by step by the IMO. These limits apply in the so-called ECA (Emission Control Area) zones. There are already plans to expand the zones. In Norwegian waters, a tax on NOx emissions is due. The NOx Fund (www.nho.no) raises a tax and finances the installation and operation of measures to reduce emissions.

The Environmental Ship Index

International

Global IMO Tier III NOx Regulations

International

Differentiated Port and Fairway Dues

Sweden

NOx Tax and NOx Fund

Norway